Adding TPMS to a Rigid Dump Truck (RDT)? Discover enhanced safety and efficiency with our seamless TPMS integration for Rigid Dump Trucks (RDT). Installing our TPMS system to your RDT is a straightforward process, completed in under 60 minutes. Our innovative ATLAS connected TPMS solution empowers fleet and site managers with real-time insights into the tyre performance of the entire fleet, 24/7, even during periods of machine inactivity.

Our new interactive ATLAS in-cab receiver enables drivers and operators to receive instant tyre alerts, ensuring comprehensive tyre monitoring. With our advanced TPMS technology, safety and performance are always at the forefront, guaranteeing a reliable and optimised operational experience for your fleet.

ATLAS can track machines on any mining/extraction site, haul road or off highway location.

After Market – The Whole Fleet

Why not fit TPMS to the whole fleet? It takes around 30 to 60 minutes to fit an ATLAS TPMS system without the need or cost of taking the machine out of action for hours. The benefits of TPMS will save the company thousands of pounds.

Even the Most Challenging of Tyres

Monitoring earthmover tyres can be challenging, whether utilising 3 piece or 5 piece rims. ATLAS TPMS has been proven to provide reliable and prompt feedback to ensure rapid action to protect a valuable asset.

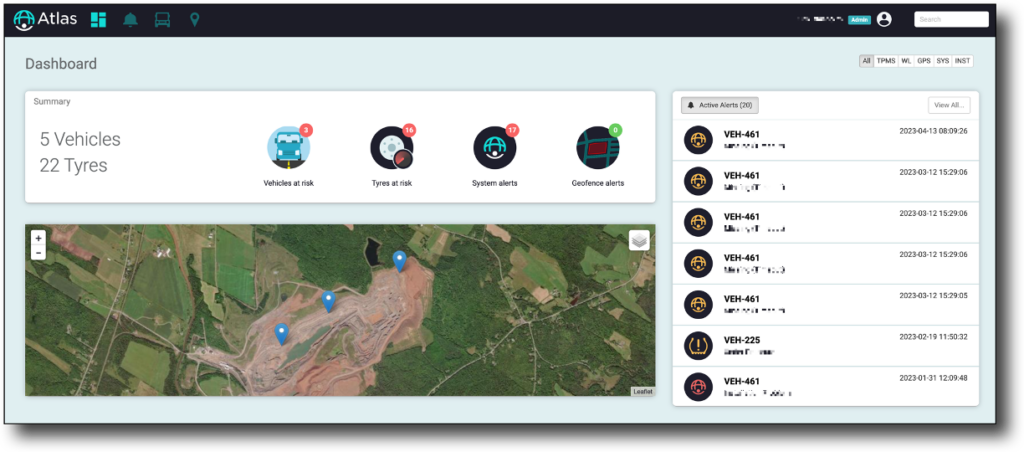

Fleet TPMS on a Dumper

ATLAS allows a fleet or site manager to manage the tyre performance of the whole fleet via the ATLAS Insight web application.

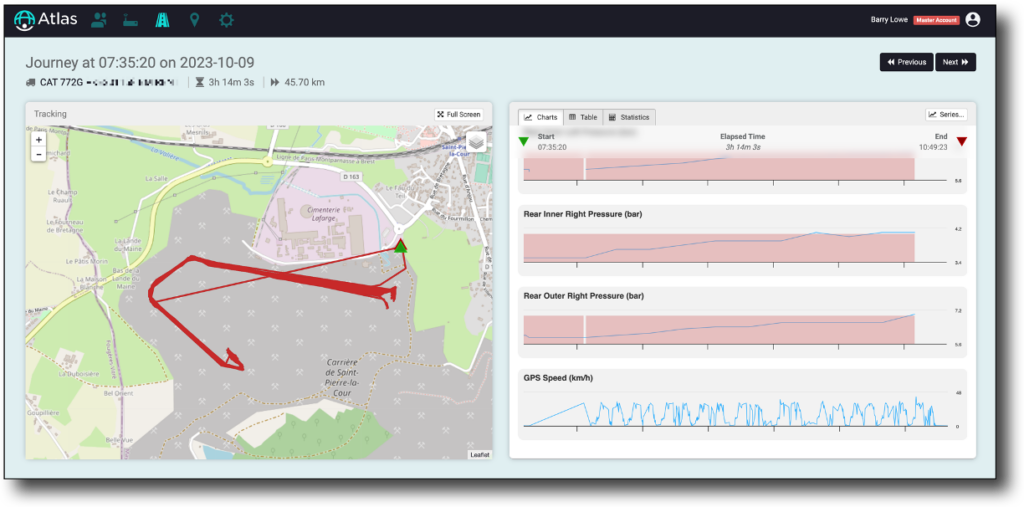

Journey cycles around the quarry

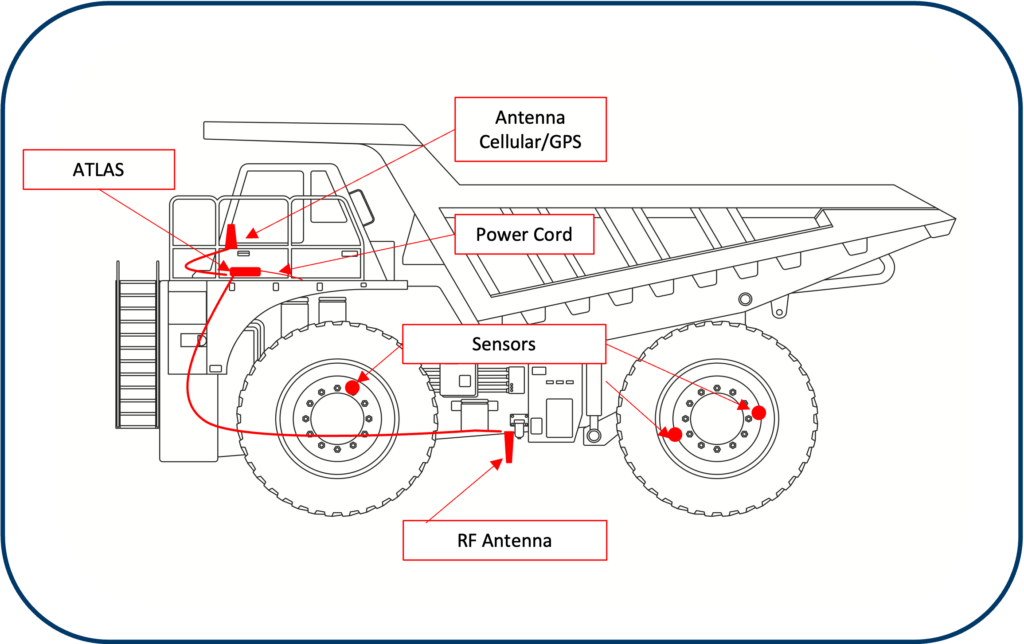

Components for Installation of TPMS on an RDT

The following components would be required for an installation:

| Part Number | Description |

| ATLAS | Fleet Gateway (ATLAS) |

| ATL2-222PR | ATLAS Power Lead |

| ATL2-850K | RF Antenna (to receive pressure readings from sensors) |

| ATL2-333AN | Cellular and GPS antennas |

| ATL2-PGTEHL | ATLAS Industrial TPMS Sensors (mounted on the valve) |

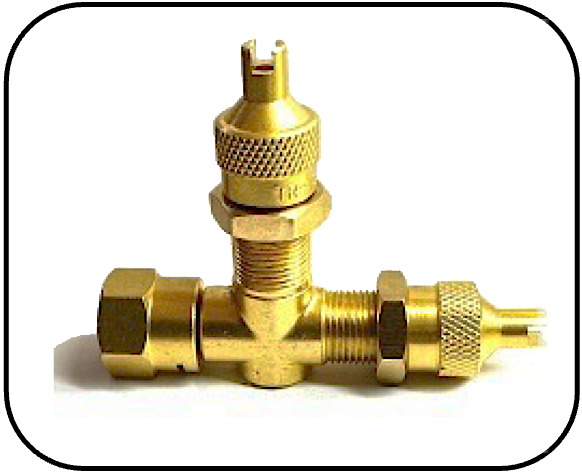

ATL2-920 T-Valve

Recommended for installation with ATL2-PGTEHL Industrial Large Bore Sensors

- The T-valves are suitable for use on all large bore (Earthmover), metal valves and standard metal commercial valves (Truck).

- The T- valve simply screws over the existing valve and forms an airtight seal.

- It works by allowing the pressure to be constantly monitored by the sensor (no need to draw the air and risk sealant blocking the valve) and allow any pressure adjustments to be made by the technician forcing air down the valve chamber.

- The sensor can sit permanently in the required position and regular inflations carried out via the other valve outlet. It’s a simple and an easy fit to undertake. The benefit being you never have to touch the sensor!

- T-valve is a low cost solution.

- Re-useable following tyre & valve change.

- Comes with two large bore metal caps.

- Reduce the need for pressure inspection.

- PPP…..Proactively Preventing Problems

Installation of ATLAS is straight forward… …..find out more

Alert Notifications

Email and Mobile App notifications whenever there is an alert generated by the ATLAS System.

| Examples of Manufacturers & Models |

| CAT: 770, 772, 773, 775, 777, 785, 789, 793, 794, 796, 797, 798 |

| Komatsu: 325, 405, 465, 605, 785, , 1500 |

| Volvo: R100E, R70D |

| Hitachi: 3500, 4000, 5000 |

| XCMG: XDM91, XDE170, XDE240, XDE300 electric |

Read More on ATLAS OTR Solutions

Top 5 Considerations for OTR TPMS

Webinar – TPMS Challenges in OTR (Off-the-Road)

Case Study: Successful Tyre Leasing Model

The integration of the ATLAS technology has been a game-changer for Genie Civil Services (GCS),…

Case Study: ATLAS OTR TPMS

Introduction Case Study: OTR TPMS – The remoteness and challenging environment of a site in…

Free TPMS Webinar – First Steps to Fleet Digitalisation

ATLAS Integration on RTG – Croatia

TPMS Installation of PressurePro TPMS and ATLAS on an RTG crane. Wow, what a spectacular…