Introduction

Case Study: OTR TPMS – The remoteness and challenging environment of a site in Guinea, West Africa presented a unique set of obstacles for the maintenance and recovery of the fleet of OTR 777E (Rigid Dump Truck) machines. Despite these challenges, the innovative technology of ATLAS TPMS played a crucial role in ensuring the optimal performance and longevity of the machine’s tyres.

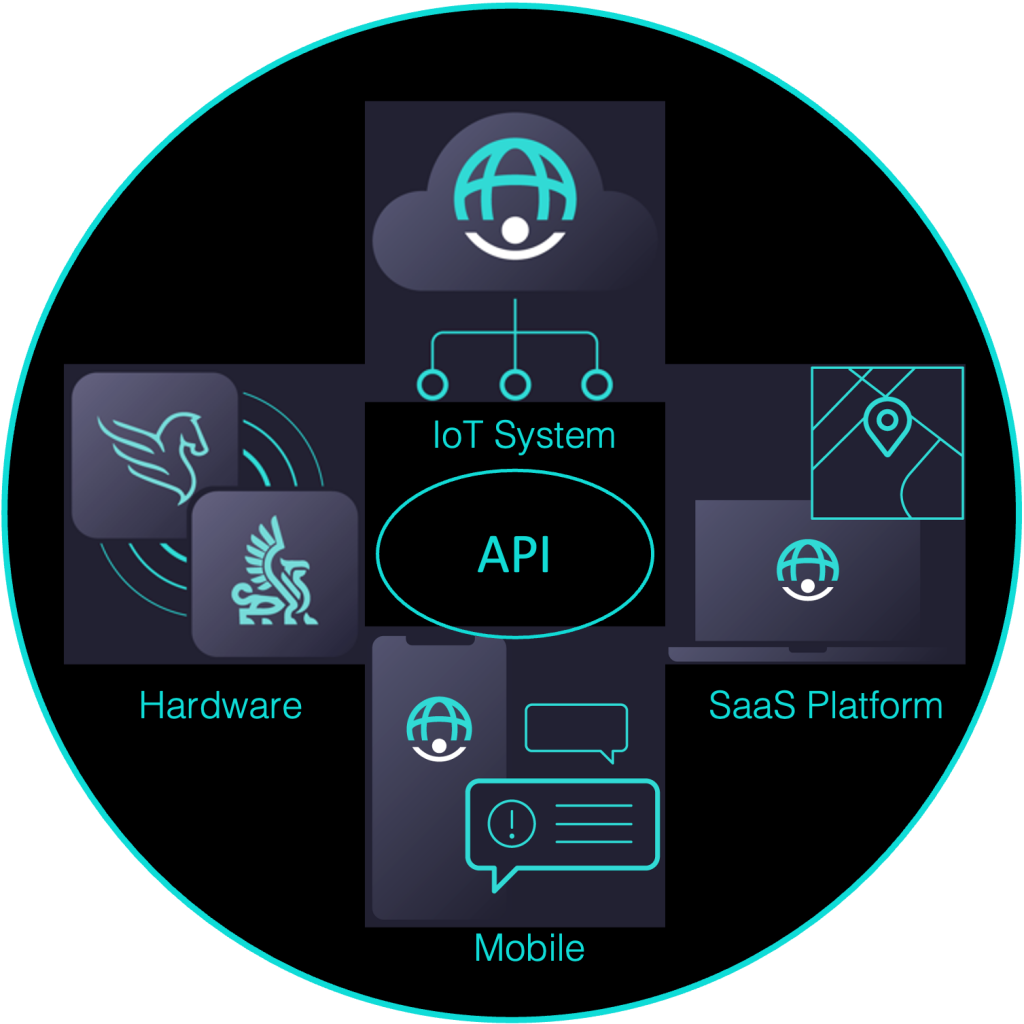

The ATLAS OTR Tyre Pressure Monitoring System (OTR TPMS)

The site set the tyre pressures on the machine to 7.1 bar (102 psi) for all wheel positions. Working closely with the site personnel, the ATLAS service base in the UK was able to track and respond to any issues that arose with the tyre pressure. This collaboration led to a series of successful interventions by the ATLAS system that prevented catastrophic tyre failure and saved the life of the tyres.

A Real-World Example

One such intervention occurred when the Right Rear Inner (RRI) tyre showed an “under pressure” alert, registering 5.9 bar (86 psi). A notification was immediately sent, and as the tyre continued to trend downwards, a cross axle alert was triggered, requiring immediate action. At the same time, the Left Rear Inner (LRI) tyre also showed an “under pressure” alert, with a loss of 1.7 bar (24 psi) in just 24 hours. This was followed by a further loss of 0.9 bar (11 psi) in just 50 minutes, indicating a catastrophic tyre failure was imminent. The ATLAS TPMS system intervened and saved the life of both the Right Rear Inner and Left Rear Inner tyres, resulting in a cost savings of over $20,000 and preventing severe downtime of the machine.

Continuous Monitoring and Real-Time Updates

The ATLAS system continued to monitor the site, providing real-time updates and advice on the fleet tyres. This ensured that the tyres were being maintained at their optimal working capacity and prevented the negative effects of severe underinflation, such as reduced tyre life, increased fuel consumption, decreased puncture resistance, and decreased safety and productivity. The integration of real-time TPMS monitoring into maintenance best practices has subsequently improved response times and proactively prevented issues through utilising the machine feedback.

Case Study OTR TPMS – Conclusion

The ATLAS TPMS solution provided significant benefits to the cost of operating the machines, including tyre life saved, reduced fuel consumption, better puncture resistance, and a safe working environment for site personnel. The ATLAS system also prevented the disruption of production by preventing tyre failure on the machines, ultimately resulting in a cost savings of approximately $20,000.

Fleet Decarbonisation: Going green isn’t just a buzzword around here – it’s a smart move!

Fleet decarbonisation and TPMS share a vital connection, offering transformative potential for sustainable practices in…

Trailer Innovation: Exploring the Benefits of Smart Trailer Technology

The latest in a series of webinars from Tough Tech. This webinar will provide valuable…

Top 5 Considerations for OTR TPMS

Webinar – TPMS Challenges in OTR (Off-the-Road)

Case Study: Successful Tyre Leasing Model

The integration of the ATLAS technology has been a game-changer for Genie Civil Services (GCS),…

Case Study: ATLAS OTR TPMS

Introduction Case Study: OTR TPMS – The remoteness and challenging environment of a site in…

Recommendation

Based on its success in the challenging environment of the Guinea site, the ATLAS 24/7 connected TPMS solution is highly recommended for fleet purchases. The solution includes a full after-sales service, including online training and manuals, and the option for an Overwatch service to ensure the operator receives the full benefits of the data insights provided by the ATLAS TPMS.